Fin Classification and Characteristics

Fin is the basic heat transfer element, its role is to expand the heat transfer area, improve the efficiency of heat transfer. The fin can be regarded as the extension and expansion of the separator; Secondly, the different forms of fins make the air form a strong turbulent flow in the flow channel, and make the flow boundary layer and the heat boundary layer break and recombine, thus strengthening the heat transfer. Finally, the fins can also improve the overall strength of the radiator and effectively expand its application range. The common fin structure forms are straight fins, louvered fins, serrated fins, porous fins and corrugated fins.

According to the fin application environment, in accordance with the tube and tube; The fins are classified in terms of heat transfer between liquids, heat transfer between liquids and gases, and heat transfer between gases and gases.

1.The structural form and characteristics of the inner and outer fins

In heat exchangers and many heat transfer equipment, the size of the convective heat transfer coefficient of the fluid on both sides of the heat transfer wall is often very unbalanced, so it is necessary to install fins on the side of the heat transfer wall.

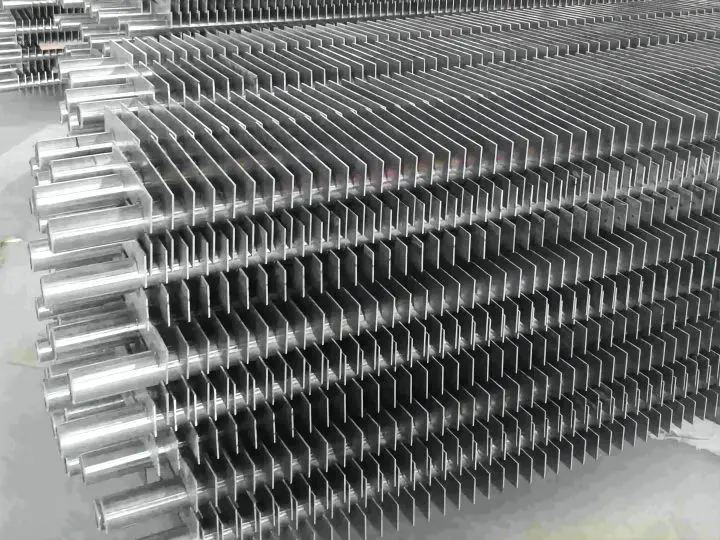

There are two kinds of finned tubes used in heat exchangers: inner finned tubes and outer finned tubes, of which outer finned tubes are more commonly used. The outer fin tube is generally formed by machining on the outer surface of the optical tube with a certain height, a certain pitch and a certain thickness of the fin. The types of finned tubes are spiral finned tubes, set finned tubes, rolled finned tubes and plate finned tubes.

The helical fin tube is widely used in the liquid or gas-liquid two-phase working medium inside the tube and the gas outside the tube, which has the effect of strengthening the airflow disturbance outside the tube and expanding the heat transfer area, thus enhancing the heat transfer and saving energy. At the same time, because of its compact structure, the metal consumption is reduced, so the use of spiral tube bundle finned tube economizer in electric field boiler can greatly save operating costs, and has been rapidly popularized and applied at home and abroad.

In order to improve the characteristics of spiral fin tube easy to accumulate ash and difficult to clean, H-type fin tube has been proposed in recent years. H-type fin tube, also known as H-type finned tube, is the two pieces of steel with an arc in the middle are symmetrically welded together with the light tube to form a fin (fin or butterfly), and the front shape is quite like the letter “H”. Due to the special groove structure of the fin surface, part of the heat transfer area in the inlet and tail separation area of the fin surface is removed, which reduces the influence of heat transfer deterioration in the inlet and tail separation area on the heat transfer of the entire fin, thereby improving the average convective heat transfer coefficient and fin efficiency of the fin, so as to achieve the purpose of strengthening heat transfer. The problem of fin burning caused by unreasonable structural design of spiral fin tube bundle is avoided.

The experimental study on the convective heat transfer and resistance characteristics of the corrugated inner fin tube shows that the overall performance of the finned tube is generally stronger than that of the light tube, and the different diameter of the tube and the form of the fin have a great effect on the heat transfer enhancement.

2.Structural form and characteristics of heat exchange fins between liquids

When the liquid is forced convection inside and outside the tube, if the heat transfer coefficients on both sides of the heat exchange wall are large, it is not necessary to use finned tubes. Such as water/water heat exchanger, when heating cold water with hot water, the heat transfer coefficient on both sides is high enough, there is no need to use finned tubes, but in order to further enhance heat transfer, threaded tubes or bellows can be used instead of light tubes; Power plant condenser, outside the tube is the condensation of water vapor, the working medium in the tube is water, the heat exchange system on both sides is very high, under normal circumstances, there is no need to use fin tubes.

3.Structural form and characteristics of heat exchange fins between liquid and gas

When the forced convection of the gas outside the tube and the forced convection of the liquid working medium inside the tube, the heat transfer coefficient outside the tube is much smaller than that inside the tube. Therefore, the thermal resistance of heat transfer outside the tube becomes the main thermal resistance that affects the total heat transfer (also known as the control thermal resistance). In this case, the enhancement of the heat transfer in the space outside the tube is usually achieved by an extended surface, that is, a ribbed surface. The results show that when 2λ/αδ<1, it is ineffective to design the heat transfer surface as a ribbed surface. When 2λ/αδ>5, the heat transfer surface can be designed as a ribbed surface to enhance heat transfer.

When the forced convection of the gas inside the tube and the forced convection of the liquid working medium outside the tube, the heat transfer coefficient inside the tube is much smaller than that outside the tube. Therefore, the heat transfer resistance in the tube becomes the main thermal resistance affecting the total heat transfer. In this case, it is necessary to add an extended surface in the tube or install a spoiler to increase the turbulence intensity and enhance the heat transfer performance on the gas side.

The ribbed surface can not only increase the total effective area involved in convective heat transfer and reduce the thermal resistance of the side heat transfer, but also make the wall temperature of the ribbed side closer to the temperature of the same side fluid. The use of extended heating surface is an effective way to strengthen heat transfer, and the application of extended surface is an important measure to reduce the volume, reduce the weight and improve the efficiency of heat exchanger. Because of this, the research and design of extended heat transfer surfaces are increasingly widely used in industry.

The use of convection heating surface inside and outside the tube can increase heat transfer, save metal consumption, and reduce ventilation resistance and working fluid flow resistance, has become the development direction of boiler and heat exchanger convection heating surface, has been more and more widely used. There are various types of extension surfaces, such as circular, square and spiral fin tubes, fin tubes with longitudinal fins, and membrane convection heating surfaces composed of longitudinal fin tubes. Due to the different heating area increased by various extended surfaces, the degree of disturbance to the fluid is also different, so they have different effects on heat transfer enhancement.

In the research of strengthening fin surface heat transfer, various methods of strengthening heat transfer are proposed, mainly the following: First, enhance the turbulence intensity of the air side, and achieve the purpose of strengthening heat transfer by constantly changing the flow direction of the air flow, mainly by stamping the fin into a corrugated shape, resulting in the type of corrugated fin. Second, the discontinuous fin surface is used to gradually disconnect the fin surface along the direction of the air flow to prevent the development of the laminar boundary layer of the air on the fin surface, so that the boundary layer is constantly destroyed on each surface, and a new boundary layer is formed in the next punch strip, and the leading edge effect of the punch strip is constantly used to achieve the purpose of strengthening heat transfer. Belonging to this kind of fin, there are slit fin and louver fin, etc.

Due to the simple and convenient structure and manufacturing of the flat fin heat exchanger, the durability of the application and its good applicability, so far, the heat exchangers widely used in refrigeration engineering (such as ammonia cooler evaporator, surface air cooler, etc.) are still widely used as the expansion surface of rectangular flat fins. Rectangular flat fins have the advantages of simple and compact structure, good for defrosting and easy manufacturing. At the same time, because they only rely on increasing the heat transfer area to strengthen the heat transfer, the heat transfer effect is poor, especially in the heat exchanger where the fluid phase in the tube changes heat and the air outside the tube is forced to flow heat, the thermal resistance of the air side is still the main thermal resistance in the whole heat transfer process.

Because the corrugated fin can increase the length of the air flow path and can cause sufficient mixing of the air flow, it is also widely used in air conditioning refrigeration. The corrugated fins can change the direction of air flow, greatly increase the air heat transfer area, and enhance the fluid disturbance. Due to the formation and separation of vortexes, the continuous development of the thermal boundary layer is weakened or destroyed, so that the heat transfer characteristics are effectively strengthened. At the same time, it also brings a large resistance loss, but the increase of heat transfer is greater than the increase of resistance. In wet conditions, the resistance of the slit fins increases more, and the system air volume will be reduced, at this time, the corrugated fin heat exchanger can be considered, and the fin spacing should not be too small.

Slotted fins have efficient heat transfer performance. When fluid passes through slotted fins, vortex first appears in the downstream, and with the increase of Reynolds number, vortex point moves upstream. As the fin spacing decreases, vortices begin to appear at a small Reynolds number. This phenomenon shows that the heat transfer coefficient is enhanced at small fin spacing due to the generation of vortices. For continuous corrugated fins, slit is beneficial to eliminate transverse vorticity and make the fluid mix more fully, thus improving the flow and heat transfer performance of the fins. The local heat transfer coefficient changes sharply at the corners and gaps of the slotted fins. The maximum value of the heat transfer coefficient appears upstream of the corner or the leading edge of the fin, while the minimum value appears downstream of the corner or the trailing edge of the fin. In dry conditions, try to use a fin with a large heat transfer coefficient, such as a slit fin, but because the resistance of the slit fin is larger, so when the same heat transfer is needed, try to choose a larger windward area, rather than a larger number of rows, in order to make full use of the advantages of the enhanced fin, without increasing its fan power.

The louver fin is a form of fin with a large heat transfer coefficient. When the fin heat exchanger needs to run alternately under dry and wet conditions, a hydrophilic coating can be added to the surface of the fin, which has little effect on the heat transfer performance, but can greatly reduce the air flow resistance under wet conditions, and the effect of the louver fin is better. In this case, louvered fins can be used as much as possible.

4.Structural form and characteristics of heat exchange fins between gases

When there is forced convection of gas outside the tube, if the heat transfer coefficients on both sides of the tube are very small, in order to enhance heat transfer, fins should be installed on both sides at the same time. If the structure is difficult, neither side can add fins. In this case, if the fins are only added on one side, there is no obvious effect on the increase of heat transfer.

For example, in the traditional tubular air preheater, the forced convection of air inside the tube is the forced convection of smoke outside the tube. It belongs to the convective heat transfer between the gases, the heat transfer coefficient on both sides is very low, and it is difficult to add fins in the tube, so a light tube can be used; In the heat pipe air preheater, although it is still the flue gas heating the air, because the flue gas and air are flowing outside the tube, the finned tube can be conveniently used on the flue gas side and the air side, so that the heat transfer is greatly increased.

5.Influence parameters of fins

Fin height: Increasing the fin height will increase the surface area, but this parameter is limited by the following factors. Fin height affects the basic parameter of mass flow, which affects heat transfer and pressure drop. The manufacturing limitation of integral fin is much greater than that of serrated fin tube. Fin efficiency decreases, and the overall fin decreases more seriously than the serrated fin; For fins less than 12 mm in height, the use of integral spiral fins is recommended. If the other parameters are kept unchanged and only the fin height is increased, the cost of the heat exchanger first decreases, then remains unchanged, and finally begins to increase again, because the increase in the heat exchange area is offset by the larger tube spacing effect, the lower gas flow rate, the lower fin efficiency and the lower fluid permeability.

Fin thickness: Smaller fin thickness can bring higher fin density, but it also reduces fin efficiency and reduces structural stiffness. The minimum fin thickness is usually 0.9mm, if used to deal with corrosive/lubricating fluids or high temperature fluids, a larger fin thickness is required, up to 4.2mm, and for small diameter cases, there will be some restrictions. The most commonly used fin thickness is 1.2mm.

Fin density (spacing) : In order to obtain the maximum surface area per unit tube length, the highest allowable fin density is needed, but too high fin density leads to excessive pressure drop, incomplete gas penetration, and increased dirt.