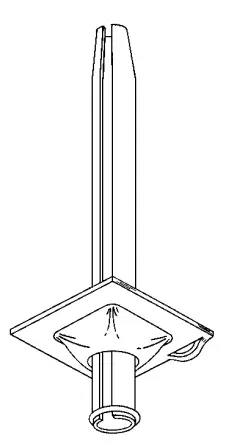

Split Set Rock Bolt

The Split Set Rock Bolt, also known as a split set bolt or friction rock bolt, is a slotted steel tube with one end tapered for easy insertion into a drill hole. The other end has a welded ring flange to hold the bearing plate. This underground mining split set stabilizer is inserted into a hole slightly smaller in diameter than the tube, using a simple driver tool fitted to the drill.

As the tube enters, its diameter is compressed and the slot partially closes. This exerts radial forces along the length of contact with the rock, providing the friction which holds the rock together. The driving force of the drill actively loads the bearing plate against the rock, making split set bolt installation quick and efficient.

CONTACT US

E-mail: sales@glorysteelwork.com

Whatsapp:86 15036167067

Mobile: 86 15036167067

SPECIFICATION

| Dia. | 33mm | 39mm | 42mm | 47mm |

| Thinkness | 2.5mm | 2.5mm | 2.5mm | 3.0mm |

| Slot Size | 10mm | 15mm | 17mm | 20mm |

| Min.Yield Strength | 78Kn | 88Kn | 95Kn | 124Kn |

| Min.breaking Strength | 103Kn | 116Kn | 123Kn | 160Kn |

| Max.Breaking Strength | 117Kn | 132Kn | 140Kn | 186Kn |

| Elongation | >16% | >16% | 16% | 16% |

| Anchoring | 4-7tons | 5-8tons | 5-8tons | 6-12tons |

| Domed Plate | 150*150*4mm | 150*150*4mm | 150*150*5mm | 150*150*5mm |

Split Set Rock Bolt for Mining and Ground Support

Split Set Rock Bolts and friction bolts are widely used for underground or surface ground support in mining, tunneling, and slope stabilization.

Split Set Rock Stabilizers are an easy and cost-effective solution to your ground support, mine roof support, and other stabilizing, holding, or anchoring problems. They are ideal for underground mining split sets applications where immediate frictional support is needed.

Typical Applications: Mines · Slopes · Tunnels

How does Split Set Rock Bolt and Friction Bolt Work

Split Set Rock Bolts consist of only two parts, a slotted tube and a matching domed bearing plate. The high-strength steel tube is slotted along its length. One end is tapered for easy insertion into a drill hole, and the other end has a welded ring flange to hold the bearing plate. With the bearing plate in place, the tube is driven into a slightly smaller hole using the same standard percussion drill that made the hole. As the tube of the split set bolt slides into place, the full length of the slot narrows, causing radial pressure to be exerted against the rock over its full contact length. This simple friction system gives split set rock bolts their excellent performance in ground stabilization.

Features & Advantages

- Made From High Strength Steel Band

- Immediate Frictional Support In Axial And Radial Direction

- Independent Supporting Without Plate

- Easy For Split Set Bolt Installation

- Simple Design, Cost Saving

- Available In Black, Cold Galvanizing Or Hot Dip Galvanized

Accessories

Bearing Plate, Driver, Pull Collar. Optional parts for split set rock bolts specifications include domed plate, bearing washer, and installation driver.

Order Split Set Rock Bolts Now

Fast delivery, certified quality, and customized dimensions for your mining support system.