What is the correct way to disassembling bearings?

Bearings in operation for a period of time, it is inevitable that there will be maintenance or damage replacement needs. In the early days, due to the lack of popularity of professional knowledge and the lack of awareness of safe operating procedures, disassembling bearings will be more “violent”. Then how is the correct way to remove the bearing?

How to disassemble the bearing?

1. It is best carried out under the guidance of experienced personnel

2. Before disassembly begins, determine the specific method to be disassembled

3. Have the necessary bearing removal tools at hand

4. When re-using or checking disassembled bearings, pay attention to avoid scratching or damaging the bearing raceway or rolling element; When removing the bearing from the bearing seat, the disassembly force is applied to the outer ring; Remove the bearing from the shaft and apply the removal force to the inner ring.

The main method of disassembling bearings?

1. Use hands or hydraulic pressure

2. Use only professional wrenches

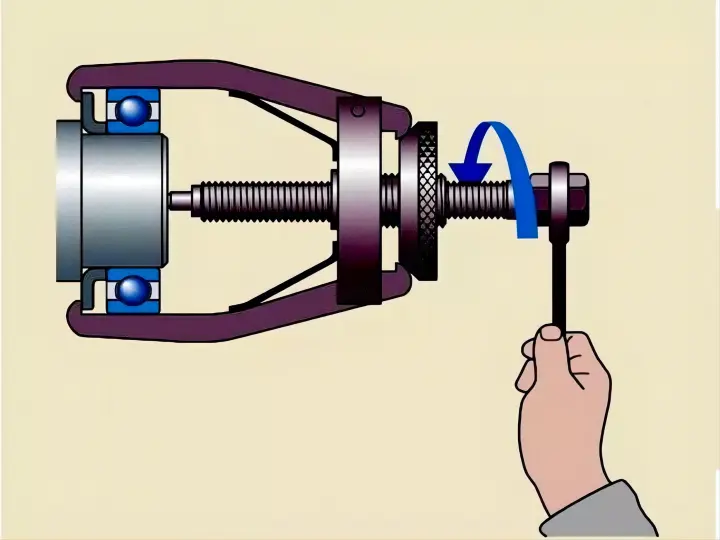

3. Use a puller

4. Use induction heating equipment (inner ring)

5. Use oiling

How to select the different tools?

Remove bearings mounted on cylindrical diameter

1. Cold disassembly

When disassembling smaller bearings, use a suitable punch to gently tap the side of the bearing ring to remove it from the shaft, or better still, use a mechanical puller

The grip should be applied to the inner ring or adjacent components. The disassembly process can be simplified if the shaft shoulder and the housing bore shoulder are provided with grooves to accommodate the puller’s grip.

In addition, some threaded holes are machined at the hole shoulders to facilitate the bolts to push out the bearings.

Large and medium-sized bearings often require more force than machine tools can provide.

Therefore, it is recommended to use hydraulic power tools or oil injection methods, or both together. This means that the shaft needs to be designed with oil holes and oil grooves.

2. Hot disassembly

When disassembling the inner ring of needle roller bearings or NU, NJ, and NUP cylindrical roller bearings, the thermal disassembly method is suitable. Two commonly used heating tools: heating rings and adjustable induction heaters.

Heated rings are typically used to install and disassemble the inner rings of small and medium-sized bearings of the same size. The heating ring is made of light alloy, has radial grooves and is equipped with an electrically insulated handle.

If inner rings of different diameters are frequently disassembled, it is recommended to use an adjustable induction heater.

These heaters quickly heat the inner ring without heating the shaft.

When disassembling the inner rings of large cylindrical roller bearings, some special fixed induction heaters can be used.

3. Disassemble the bearing installed on the conical shaft diameter

Small bearings can be removed by using a mechanical or hydraulically powered puller to pull the inner ring. Some pullers are equipped with spring operating arms. Using this puller with a self-centering design can simplify the procedure and avoid damage to the shaft diameter. If the puller claw cannot be used on the inner ring, the bearing should be removed through the outer ring, or by using a puller combined with a puller.

When using the oil injection method, the disassembly of medium and large bearings will be safer and simpler. This method injects hydraulic oil between two conical mating surfaces through oil holes and oil grooves under high pressure. Friction between the two surfaces is greatly reduced and creates an axial force that separates the bearing and shaft diameter.

4. Disassemble the bearing on the adapter sleeve

For small bearings installed on straight shafts with adapter sleeves, you can use a hammer to knock the small steel block evenly on the end face of the inner ring of the bearing to disassemble it. Before this, the adapter sleeve locking nut needs to be loosened several turns.

For small bearings installed on an adapter sleeve with a stepped shaft, a hammer can be used to knock the small end face of the adapter sleeve lock nut through a special sleeve to remove it. Before this, the adapter sleeve locking nut needs to be loosened several turns.

For bearings mounted on adapter sleeves with stepped shafts, the use of hydraulic nuts can make bearing removal easier. For this purpose, a suitable stop device must be installed close to the piston of the hydraulic nut. The oil filling method is a simpler method, but an adapter sleeve with oil holes and oil grooves must be used.

5. Disassemble the bearing on the withdrawal sleeve

When disassembling the bearing on the withdrawal sleeve, the locking device (such as locking nut, end plate, etc.) must be removed. For small and medium-sized bearings, lock nuts, hook wrenches or impact wrenches can be used to disassemble them.

For medium and large bearings installed on the withdrawal sleeve, they can be easily removed using hydraulic nuts.

It is recommended to install a stop device only behind the hydraulic nut at the shaft end.

This stop device prevents the withdrawal sleeve and hydraulic nut from flying out of the shaft when the withdrawal sleeve is suddenly separated from the mating position.

Important points to note

1. Be sure to check whether there are cracks, sharp sources, breaks, fragments or deformations before disassembly;

2. When using the press, all parts should be stable and not shake or vibrate; when pressing the shaft, the center of the shaft must be aligned with the center of the hammer; do not hold the shaft with your hands when applying force; place a catcher to catch the shaft or bearing to avoid fall to the ground;

3. When using the puller, make sure that the claws of the puller are firmly clamped on the side of the bearing; align the end of the load bolt on the puller with the shaft; if the claws become loose during operation, stop immediately, change the position and secure it , resume operation; if the bearing fails to come out after applying normal disassembly force, do not apply excessive force to the puller and use other methods.

4. When using a professional wrench (removing the socket), please use a wrench with a locking nut of appropriate size; if the locking nut is too tight, do not hit the handle of the wrench with a hammer;

5. When using the bearing oiling method, slowly inject the oil, and immediately stop the oil injection when the inner ring moves along the axis; The cone-hole bearing may fly away from the bearing at high speed, and a nut must be installed at the end of the shaft to prevent it from flying away;

6. When using induction heating equipment, do not place flammable materials (such as oil or gas) near the working area; When bearings are used repeatedly or need to be inspected, do not heat more than 120 ° C; Do not touch the heated bearing or surrounding parts without gloves; After heating, remove the bearing (inner ring) from the shaft immediately; If the bearing inner ring is difficult to move during early disassembly, stop the operation, reheat the bearing (inner ring), and then continue the operation.

Stepped shaft – Glorysteelwork specialized in supplying forged stepped shaft ,roller. Glorysteelwork has forged stepped shaft processing center, can manufacture forged bars, forged parts, drills, shaft, roller etc. If you have any purchas plan, just contact us!