Application Status and Prospects of Hot Rolled H-Shaped Steel for Construction

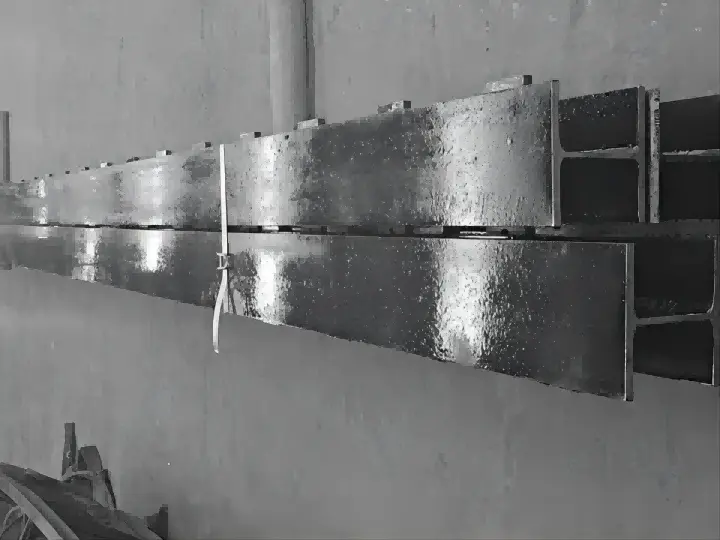

Hot-rolled H-shaped steel is a new type of economical construction steel. Its web (often called the waist) is perpendicular to the two flanges (often called the legs), and its cross-section is shaped like the English letter “H”, so it becomes an H-shaped steel. And because the inner and outer sides of the flange are parallel to each other, the leg ends are straight and have sharp edges, it is also called “parallel leg I-beam”.

1. Types and characteristics of H-shaped steel for construction

(1) Hot rolled H-shaped steel: has the advantages of high dimensional accuracy, high production efficiency, low consumption, low comprehensive cost, small residual stress, short construction period, etc.; However, the product specifications are fixed, the section flexibility is poor, the amount of steel is slightly larger, and the procurement cycle is long with specifications.

(2) Welded H-shaped steel: has the advantages of section size can be customized according to user requirements, flexible section changes, etc.; But cutting, welding metal consumption is large, low production benefits; Shape and quality are not easy to guarantee; Large residual stress and other shortcomings.

(3) High-frequency welding H-beam steel: has the advantages of fast welding speed, low thermal effect, easy to control deformation, and can weld H-beam steel of different material combinations; But only applicable to small sections.

(4) Corrugated web H-shaped steel: web with pressed steel plate, improve the local stability of the web, used as a beam member, can save steel; But not applicable to compression members, tension members; Can not directly withstand dynamic load; And the welding connection is complicated.

2. Advantages of hot-rolled H-shaped steel

(1) High structural strength. Compared with I-steel, the section modulus is large, and the metal can be saved by 10%-15% under the same bearing conditions.

(2) The design style is flexible and rich. In the case of the same beam height, the opening of the steel structure is 50% larger than that of the concrete structure, which makes the building layout more flexible.

(3) Light structural weight. Compared with the concrete structure, the reduction of the structure’s self-weight reduces the internal force of the structure design, which can make the building structure foundation treatment requirements low, the construction is simple and the cost is reduced.

(4) The use of H-shaped steel can effectively protect the environment, which is reflected in three aspects: first, compared with concrete, dry construction can be used, resulting in less noise and less dust; Second, due to the reduction of self-weight, less soil extraction for foundation construction, less damage to land resources, in addition to a large reduction in the amount of concrete, reduce the amount of rock excavation, conducive to the protection of ecological environment; Third, after the service life of the building structure expires, the amount of solid waste generated after the structure is dismantled is small, and the recycling value of scrap steel resources is high.

3. Application advantages of hot-rolled H-shaped steel in buildings and steel structures

(1) Good mechanical properties of cross section distribution

(2) No need for welding, high quality accuracy, efficient production, low consumption;

(3) Small residual stress, high bearing capacity

(4) The connection is convenient, easy to install, and the construction period is short

(5) Easy to standardize, low comprehensive cost

4. Use and application range of H-shaped steel

It is widely used in beam and column members of steel structures in industrial and civil buildings. Steel structural support for industrial structures. Steel pile and supporting structure for underground engineering. Chemical and electric power and other industrial equipment structure. Long span steel bridge members. Ship, machinery manufacturing frame structure. Train, automobile, tractor girder support. Port conveyor belt, highway baffle bracket, etc.

5. Major problems faced

At present, the main problem of hot-rolled H-shaped steel for construction is the disconnection between supply and demand. The steel structure industry has a large space for future development, which is consistent with the double carbon emission reduction policy, but the current product standards of hot-rolled H-shaped steel and the application standards of steel structure engineering are still not coordinated and not integrated, and it is urgent to integrate and urgently need the standards of hot-rolled H-shaped steel applicable to construction projects.

First, the product standard of hot-rolled H-shaped steel is not coordinated with the engineering standard in terms of tolerance error, width-thickness ratio and other indicators. For example, the flange width-thickness ratio of some wide-flange and thin-wall hot-rolled H-beams cannot meet the seismic design requirements; Some error control is not required in the product standards, which may lead to components that meet the requirements of steel products not meeting the steel structure construction quality acceptance standards and cannot be accepted.

Second, the variety is single. At present, the domestic H-shaped steel factory only stays in the completion of the production of H-shaped steel, and the redevelopment of the product is all completed by the steel structure manufacturing factory downstream of the industrial chain, which is easy to cause energy waste, high cost, and uneven product quality.

Third, due to long-term design habits, building structure designers are generally unfamiliar with the application and advantages of hot-rolled H-shaped steel, and the relevant design software and steel structure connection application manual are not convenient and easy to use, which hinders the promotion and application of hot-rolled H-shaped steel from the design source.