Rail Clip

The concept of rail clip should be born from the rail fastening system. It is an accessory used to fasten the rail. It has a long history of development and different forms and methods of use.

The earliest train tracks were fixed on wooden sleepers. At that time, hook head spikes were used to fix the track. Later, when cement sleepers were used for the track, spring bars were widely used. With the development of hoisting rails, more professional rail presses for hoisting rails have been produced. These rail presses hold down the rails by bolting the upper cover.

GloryRail is a rail systems specialist with over 20 years of experience in the industry. Rail clips are available for various rail systems. Products include spikes, clips, clamps, and crane rails. As a professional rail system supplier. Glorysteelwork understands the needs of customers better, and can better provide solutions for the problems encountered by customers. We usually divide rail clips into two application scenarios. One is for the train track system and one is for the crane track system.

CONTACT US

E-mail: sales@glorysteelwork.com

Whatsapp:86 15036167067

Mobile: 86 15036167067

RAIL CLIPS FOR RAILWAY

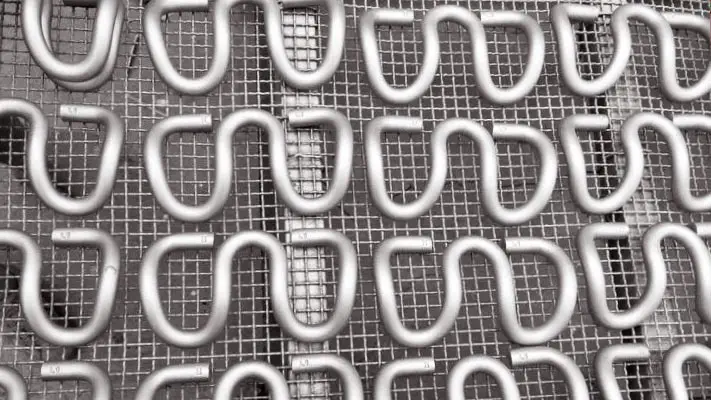

Rail clips used in the train track system are divided into two categories: spikes and clips according to the difference in track sleepers. At present, some railway lines and many mining railways still use spikes to fix the track. Most modern railways use spring clips. Various models of spikes and clips are supplied by Glorysteelwork. At present, the road studs we export to the American market are mostly used in some forest farm tracks. The clips are used in many international line constructions. Including E-type clips PR clips, SKL clips, fast clips, etc.

Glorysteelwork offers various models of rail presses for crane rails. Types can be divided into two types. Bolted rail grips and welded rail grips. The material is high-strength steel. Bolts use grade 8.8 and 10.9 bolts. Shear and lateral forces are guaranteed. Bolt sizes are M16, M20, and M24.

The welded pressure rail is composed of two parts: the base and the upper cover. The base is welded on the steel backing plate or steel beam, and the upper cover can be slidably adjusted. Finally, it is fixed by tightening the bolts. Welded rail presses are divided into single-hole and double-hole. The dual-hole rail press has the greater lateral force to ensure the smooth operation of heavy equipment.

The bolted rail clips have no base and do not require welding. Installation is simple and convenient. Directly tighten the bolts so that the rail presser is pressed against the rail. Mostly used for light lifting equipment. The same bolt type rail press is also divided into the single hole and double hole.

Rail clips for cranes

Glorysteelwork offers various models of rail presses for crane rails. Types can be divided into two types. Bolted rail grips and welded rail grips. The material is high-strength steel. Bolts use grade 8.8 and 10.9 bolts. Shear and lateral forces are guaranteed. Bolt sizes are M16, M20, and M24.

The welded pressure rail is composed of two parts: the base and the upper cover. The base is welded on the steel backing plate or steel beam, and the upper cover can be slidably adjusted. Finally, it is fixed by tightening the bolts. Welded rail presses are divided into single-hole and double-hole. The dual-hole rail press has the greater lateral force to ensure the smooth operation of heavy equipment.

The bolted rail clips have no base and do not require welding. Installation is simple and convenient. Directly tighten the bolts so that the rail presser is pressed against the rail. Mostly used for light lifting equipment. The same bolt type rail press is also divided into the single hole and double hole.

Get a quote today

What is Stainless Steel?

Stainless steel is a type of corrosion-resistant steel designed to resist rust, oxidation, and chemical damage. Its corrosion resistance comes from alloying elements such as chromium, nickel, and molybdenum, which enhance durability in challenging environments. Different grades and alloys of this material provide varying levels of resistance to air, water, steam, and chemical media, including acids, alkalis, and salts.

Selecting the right stainless steel material depends on the intended application:

- Industrial construction: structural components, machinery parts, and support frames.

- Marine and coastal environments: high chloride resistance to prevent corrosion.

- Chemical processing: acid-resistant alloys ensures long-term stability and safety.

OUR PRODUCTS

We offer a wide range of products in stainless grades, suitable for diverse industrial and construction needs. These products naturally support various applications while maintaining durability and precise dimensions. Using category-specific pages for plates, bars, and tubes allows you to target long-tail keywords like plate suppliers, tubes for construction, and round bar price in stainless grades.

Stainless Steel Plate

Available in 304, 316, 430, and other grades, ideal for industrial, architectural, and fabrication applications.

Stainless Steel Bar

Round, square, and flat bars in multiple sizes, perfect for machinery, structural components, and custom fabrication.

Why Choose Glorysteelwork?

- Global Export Expertise – Years of experience delivering worldwide ensure timely and reliable shipments.

- Precision Processing – Cutting, polishing, and shaping services ensure accurate dimensions for every application.

- Wide Range of Grades – We offer 304, 316, 430, and custom alloys to meet different industrial requirements.

- Trusted Supplier – Collaboration with TISCO, BAOSTEEL, and LISCO guarantees top-grade materials.

Get Stainless Steel Price & Support

Looking for reliable steel suppliers? Contact Glory Steel Work today for competitive quotations, technical guidance, and detailed specifications to ensure your project uses the best-suited grade and material.